随着新能源车进入高速成长期,超声波金属焊接技术已广泛应用于新能源汽车锂电池行业,新一轮动力电池产能扩建也正在全球范围内启动。为进一步适应市场发展的需求,利元亨通过对超声金属焊接技术和工艺的研发,在提升现有电芯体系的超声工艺能力的基础上,拓展新工艺、新设备和新智造的开发和应用,推出系列化超声波金属焊接设备。

As new energy vehicles enter a period of rapid growth, ultrasonic metal welding technology has been widely used in the new energy vehicle lithium battery industry, and a new round of power battery capacity expansion is also being launched globally. In order to further meet the needs of market development, Lyric Robot has expanded the development and development of new processes, new equipment and new intelligent manufacturing on the basis of improving the ultrasonic process capability of the existing cell system through the research and development of ultrasonic metal welding technology and processes. Application, launched a series of ultrasonic metal welding equipment.

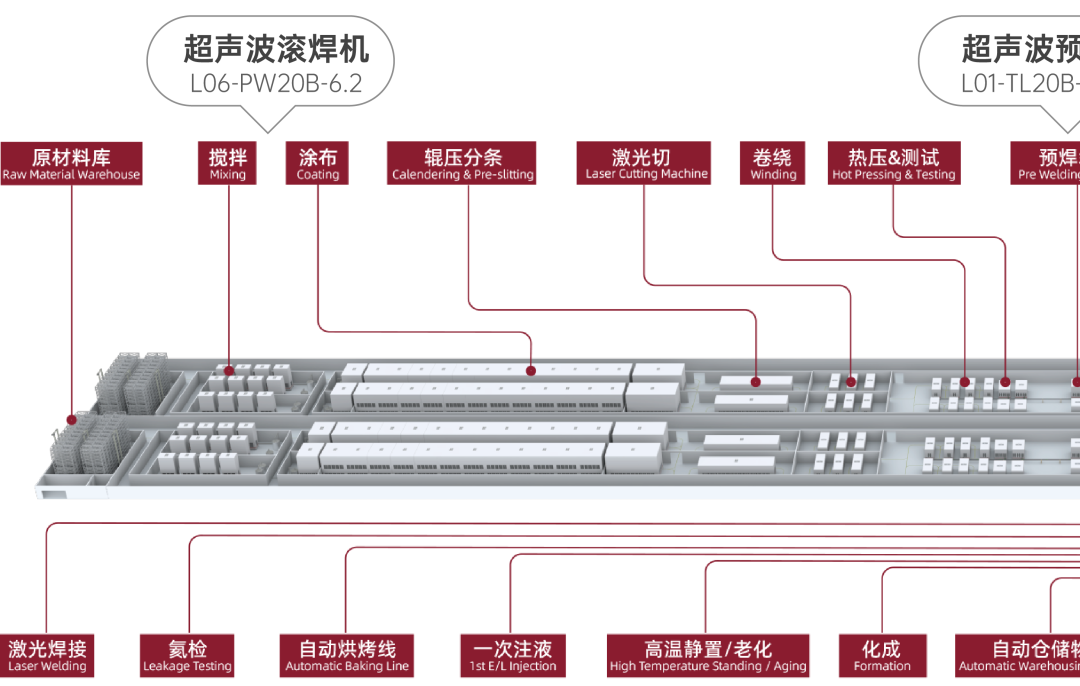

△?超声焊接技术在锂电产线上应用(左右滑动查看)

01

型谱系列化布局,全面覆盖锂电类型

Type spectrum series layout, comprehensive coverage of lithium battery types

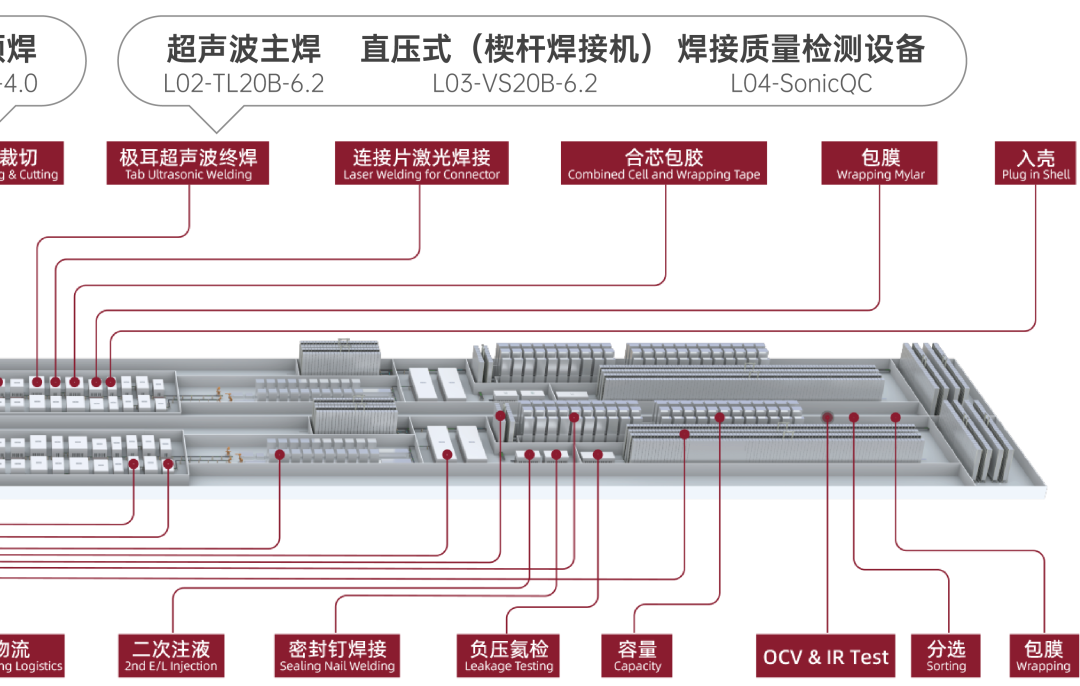

△超声金属焊接产品系列

利元亨超声波金属焊接机型谱现已开发4款,应用于卷绕和叠片工艺的电芯组装段预焊和主焊工位,解决连接极耳、极耳和连接片/转接片的焊接问题。应用范围涵盖圆柱、方形铝壳、长电芯、软包等多种电池形态的生产制造,现已申请专利20项,获专利授权10项。

Lyric Robot Ultrasonic Metal Welding Machine Spectrum has now developed 4 models, which are used in the pre-welding and main welding stations of the cell assembly section of the winding and lamination process to solve the problems of connecting tabs, tabs and connecting pieces/adapters. Welding problem. The scope of application covers the production and manufacture of various battery forms such as cylinder, square aluminum case, long battery cell, soft pack, etc. 20 patents have been applied for and 10 patents have been authorized.

02

创新双控模式,提升焊接质量

Innovative dual control mode to improve welding quality

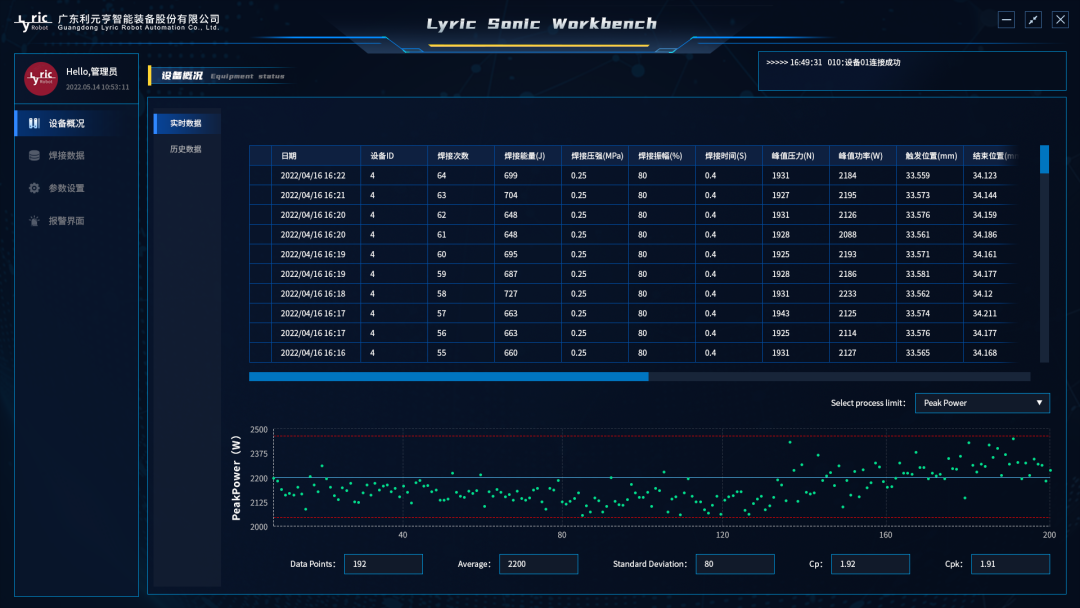

△Lyric Sonic Workbench

首创“双控焊接模式”,即采用能量焊接和深度焊接两种模式控制焊接过程,配备强大的Lyric Sonic Workbench软件,有效拓宽调参工艺窗口,减少虚焊和过焊,并提供多达10种焊接工艺数据,创新性增加对极耳焊接后变形程度的数据监测。设备在实时预判焊接质量、高度检测不良件流入与流出、识别焊接系统异常等方面具有显著优势。

The first "dual control welding mode", that is, two modes of energy welding and deep welding are used to control the welding process. Equipped with powerful Lyric Sonic Workbench software, it can effectively expand the parameter adjustment process window, reduce false welding and over welding, and provide up to 10 kinds of welding. Welding process data, innovatively increase the data monitoring of the deformation degree of the tab after welding. The equipment has significant advantages in real-time prediction of welding quality, high detection of the inflow and outflow of defective parts, and identification of abnormality in the welding system.

03

恒压触发微秒读取,提升工艺效能

Constant voltage triggers microsecond reading to improve process efficiency

以恒压力触发超声、微秒级超快读取速度,在行业内首次实现对2层铜箔或1层铝箔差异的厚度检测,有效识别多层、少层、内折和褶皱等问题。实现主焊超声开始位置波动小于0.05mm,性能提升明显。将压力和振幅分段控制焊接,兼顾了平齿焊接的强度和外观,提升现有超声焊接设备的工艺效能。

Triggered by constant pressure ultrasonic, microsecond ultra-fast reading speed, it is the first time in the industry to realize the thickness detection of the difference between 2 layers of copper foil or 1 layer of aluminum foil, and effectively identify problems such as multiple layers, few layers, inward folds and wrinkles. The fluctuation of the ultrasonic starting position of the main welding is less than 0.05mm, and the performance is improved obviously. The welding pressure and amplitude are controlled in sections, taking into account the strength and appearance of flat tooth welding, and improving the process efficiency of existing ultrasonic welding equipment.

04

高标准实验室,面向行业开放

High-standard laboratory, open to the industry

利元亨超声金属焊接实验室现已对外开放,配有拉力测试机、德国激光位移计、德国LEICA金相显微镜、基恩士VHX-950F显微镜等检测设备,为客户提供设计评估、样件测试、微观分析、拉力测试、工艺参数优化等项目的技术服务。利元亨超声波技术团队围绕客户需求和锂电装备发展趋势,与客户进行相关技术研讨,探索现有电芯体系下的超声工艺瓶颈和解决方案,业内已有多家锂电企业与利元亨超声金属焊接实验室达成合作意向。

Lyric Robot Ultrasonic Metal Welding Laboratory is now open to the public, equipped with testing equipment such as tensile testing machine, German laser displacement meter, German LEICA metallographic microscope, Keyence VHX-950F microscope, etc., to provide customers with design evaluation and sample testing , microscopic analysis, tensile test, process parameter optimization and other technical services. Focusing on customer needs and the development trend of lithium battery equipment, Lyric Robot''s ultrasonic technical team conducts relevant technical discussions with customers to explore ultrasonic process bottlenecks and solutions under the existing battery system. There are many lithium battery companies in the industry and Lyric Ultrasonic Metal Welding laboratory reached a cooperation intention.