在动力电池极耳焊接中,0.1mm偏差即可导致电芯性能骤降;120层铜箔焊接中,能量波动0.1%即可能引发过焊风险。工业4.0时代,精度即生命线。

利元亨超声波焊接技术,以微米级控制、AI智能监控、全场景适配三大核心优势,为新能源、半导体、汽车制造提供“高精度焊接”终极方案!

Lyric超声波焊接机多项核心技术突破瓶颈,实现焊点稳定可靠。

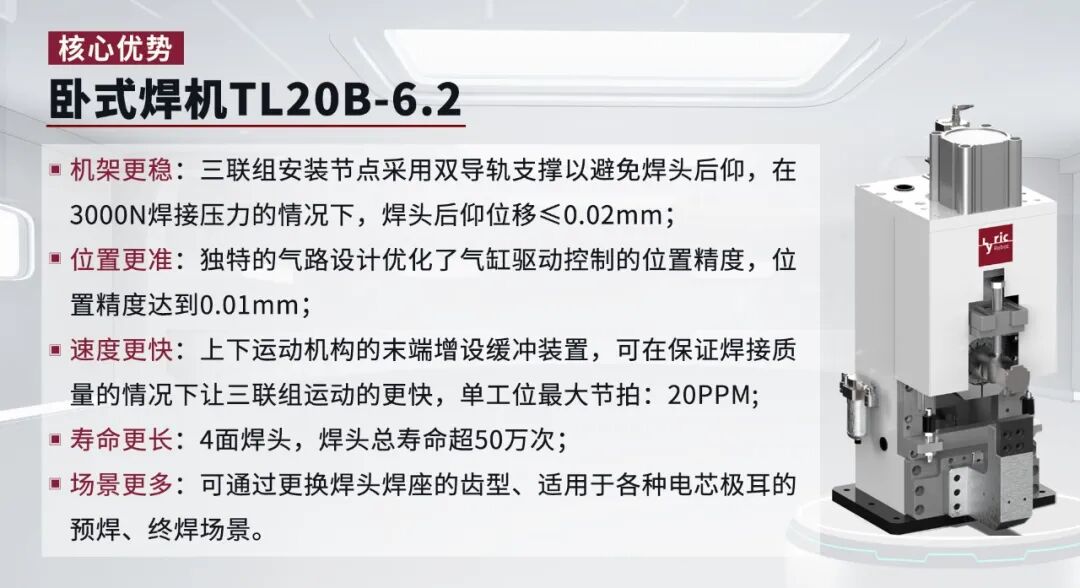

卧式焊机TL20B-6.2独创双导轨机架设计,3000N高压下焊头后仰位移≤0.02mm,攻克行业精度难题!

高速焊机HSP20B-6.2单次焊接提速1秒,单工位节拍高达20PPM。

直压式焊机VS20B-6.2突破8000W功率极限,62mm×12mm大面积焊接一次性焊透120层铜箔,兼容铜箔、铝箔等多材料组合,革新针对大焊印面积焊接两次的传统做法。

利元亨第三代超声波焊机采用电压与气压自适应技术,确保稳定输出;结构优化,响应迅速,大幅提升效率;多重安全防护,保障操作可靠;融合AI智能算法,实现焊接质量实时监控与工艺智能优化。

?动力电池领域:极耳焊接优率99.95%,助力客户突破产能瓶颈。

?汽车制造领域:金属线束焊接场景中,用超声波焊接取代传统的电阻焊,焊接点电阻更低、焊接过程中能耗更低、综合成本更低、导电性能更好。

?40+专利技术构筑护城河,恒振幅控制精度达3μm。

无论是微型电池的精密焊接,还是新能源汽车的大型模组组装,Lyric超声波焊接机都以“稳定如一的性能、持续进化的智慧”赢得信赖,以“精准、高效、智能”重新定义焊接标准,为全球客户提供从电芯极耳到线束终端的全场景焊接解决方案。

The Technology of the Industry丨Lyric Ultrasonic Welding Equipment Constructs the Ultimate Solution for "High-Precision Welding"!

In power battery tab welding, a mere 0.1mm deviation can cause a sharp decline in cell performance; in 120-layer copper foil welding, just 0.1% energy fluctuation may trigger over-welding risks. In the Industry 4.0 era, precision is the lifeline.

Lyric Ultrasonic Welding Technology delivers the ultimate " High-Precision Welding " solution for new energy, semiconductor and automotive manufacturing industries, with its three core advantages: micron-level precision control, AI-powered intelligent monitoring and full-scenario adaptability.

The Lyric ultrasonic welding machine has achieved breakthroughs in multiple core technologies and realized stable and reliable welding spots.

The horizontal welding machine TL20B-6.2 features an original dual-rail frame. Under a high pressure of 3000N, the backward displacement of the welding head is less than or equal to 0.02mm, thus solving the precision problem in the industry.

More Stable Frame: The triple-unit mounting node adopts dual-guide support to prevent welding head tilting. Under a welding pressure of 3000N, the tilting displacement of the welding head is ≤0.02mm.

Higher Positioning Accuracy: The unique pneumatic circuit design optimizes the position control accuracy of cylinder drive, achieving a positioning accuracy of 0.01mm.

Faster Speed:

The addition of a buffer device to the vertical movement mechanism allows the triple-unit system to operate at higher speeds while ensuring welding quality. Maximum single-station cycle rate: 20 PPM.

Longer Lifespan:

Equipped with a 4-sided welding head, the total service life exceeds 500,000 cycles.

Broader Applications:

By replacing the tooth profiles of the welding head and base, the system can adapt to various pre-welding and final-welding scenarios for battery cell tabs.

The high-speed welder HSP20B-6.2 achieves 1-second faster per weld cycle, with single-station throughput reaching 20 PPM (parts per minute)– delivering 30% productivity boost.

Key Features: Combines the flexibility of pneumatic actuation with the rigidity of servo drive, enhancing speed while preventing foil cracking caused by rigid impact.

Applications: Welding of tabs for prismatic aluminum-shell battery cells, welding of tabs for pouch battery cells, welding of tabs for blade battery cells, welding of tabs for solid-state batteries, terminal welding for wire harnesses.

Single welding operation is 1 second faster than conventional welders.

The direct-pressure welder VS20B-6.2 shatters industry limits with 8,000W peak power, achieving single-pass penetration on 120-layer copper foils (62mm×12mm weld area) while maintaining multi-material compatibility (copper/aluminum foils). This revolutionizes the conventional two-pass approach for large weld areas!

Capable of welding 120 layers of 36×10mm + 3mm nickel-plated copper TABs at 8,150W power, delivering excellent weld quality.

Features a 62×12mm weld imprint design with uniform amplitude distribution validated by simulation analysis.

Features: It adopts a two-point support full-wavelength welding head design, which enables one-time welding for materials with a size of 62mm x 12mm and 120 layers of copper foil.

Large area: The area of the welding region is 62mm x 12mm.

High power: The power can reach up to 8000W.

One-time welding: It can be formed by welding once, without the need for a second welding.

Lyric’s 3rd-Gen Ultrasonic Welder integrates adaptive voltage air pressure technology for stable output, structural optimization for rapid response and enhanced efficiency, and multi-layer safety protection for operational reliability. Powered by AI-driven algorithms, it enables real-time weld quality monitoring and intelligent process optimization.

Enhanced Stability: Voltage Adaptive Control + PFC ensures consistent output power unaffected by grid fluctuations. Pressure Adaptive System + Constant Amplitude Technology maintains stable amplitude output across varying pressure conditions.

? Higher Speed: Proprietary frame structure, buffering system, and pneumatic circuit design drastically improve response time. Achieves 3-second welding cycles, significantly boosting production efficiency.

? Enhanced Safety: It supports the dual-control mode of welding depth and welding energy, effectively preventing incomplete welding and over-welding. It also has functions such as real-time monitoring of the collapse ratio, anti-empty welding, anti-hand-pressing, trigger position monitoring, automatic tracking of anti-temperature drift frequency and anti-wrinkle, ensuring the safety of operations.

? Advanced Intelligence: Based on AI model inference technology, it realizes the real-time monitoring of welding quality and the analysis of production process capabilities, comprehensively improving the intelligent level of the equipment and the controllability of the process.

In the power battery sector, our tab welding achieves a 99.95% excellence rate, enabling customers to break through production capacity bottlenecks.

For automotive manufacturing applications, our ultrasonic welding technology replaces traditional resistance welding in metal wire harness production, delivering lower joint resistance, reduced energy consumption, decreased overall costs, and improved conductivity.

With over 40 patented technologies establishing our competitive advantage, we maintain constant amplitude control precision within 3 microns.

Lyric ultrasonic welders deliver reliable performance for applications ranging from precision microbattery welding to large-scale new energy vehicle module assembly, earning industry trust through their ''uncompromising consistency and continuously evolving intelligence.'' We are redefining welding standards with precision, efficiency and smart technology, offering global customers complete end-to-end welding solutions - from battery cell tabs to wire harness terminals.