6月11日,第十八届(2025)国际太阳能光伏与智慧能源(上海)大会在国家会展中心隆重举行。欧普泰针对光伏产业不同应用场景的检测需求,创新采用双展区7.1H-B120(光伏电站Ai检测服务展区)与2.1H-B220(组件Ai检测展区),双馆联动,全方位展示欧普泰作为光伏电站Ai智能检测服务提供商、智能组件工厂Ai质控专家的创新应用,成为展会首日最受瞩目的焦点之一。

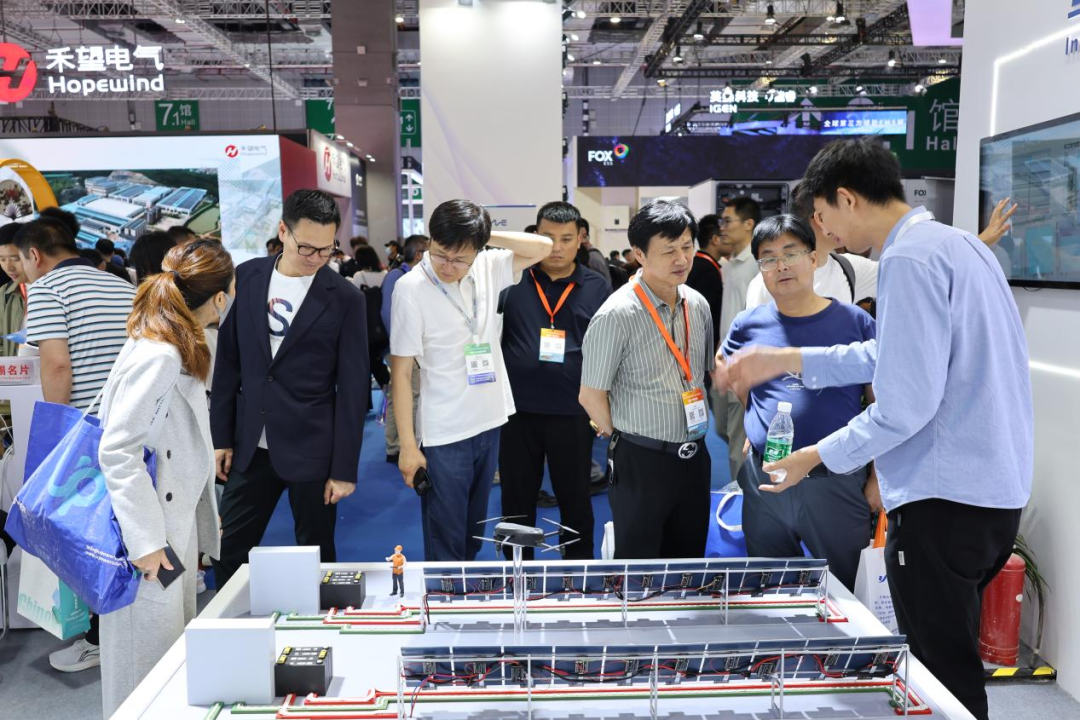

7.1H-B120(光伏电站Ai检测服务展区)

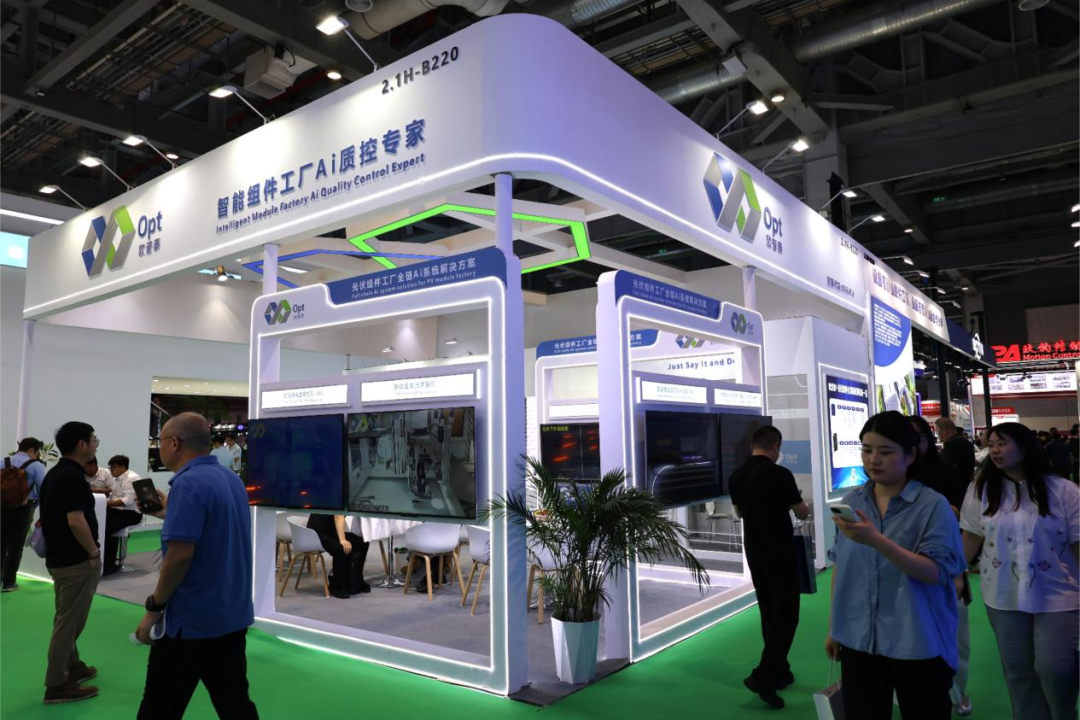

2.1H-B220(组件Ai检测展区)

1

7.1馆:Ai检测服务系统重塑电站管理模式

在7.1H-B120展位,欧普泰重点展示了旗舰产品“泰阳”系统。该系统集成了无人化智能巡检、可视化运维管理、精细化故障诊断及数字化集中管控四大核心功能,通过欧泰验检通?、欧能智增通?和资产评估等全方位服务解决方案为EPC、电站业主、运维商和电站交易方等各方主体,提供电站运营成本优化、发电收益增益和资产质量与寿命的全面评估与分析。

展位现场,行业专家与专业客户不仅亲自互动体验了泰阳?系统的电站组件质量评定与缺陷信息,还通过沙盘模拟了解了欧泰验检通?和欧能智增通?服务产品的服务全流程。在光伏行业切换至高质量发展的当下,为电站资产保值增值、增发电量和增厚发电收益提供了及时的全套解决方案。

受主办方邀请,欧普泰销售管理部总经理赵俊下午在媒体中心接受了专访。赵总表示光伏组件的缺陷有很高的隐蔽性。EL检测是目前衡量组件质量的终极解决手段,达到类似“x光”一样的效果,对组件内部缺陷进行检测,包括但不限于隐裂、断栅和明暗片等200+种缺陷。EL检测是目前唯一的内部缺陷检测手段,是审查组件健康程度与电站运行状态的终极手段。这种检测手段贯穿了组件的并网验收环节、组件的生产运维环节、电站的交易环节、电站的出险理赔环节等不同场景。

赵总进一步提到,欧普泰在EL全检的服务过程中,还提供额外的服务附加值,包括但不限于电力拓扑还原、全站3D数字孪生和组件级运维导航等功能,解决了长久以来运维缺陷精准定位难题,为提高运维效率提供了实用的工具。

2

组件Ai检测技术引领质量革命

在2.1H-B220展位,现场首次亮相三款明星产品-接线盒激光焊接机,3D接线盒虚焊检测(Ai)以及应用在边框生产线上的铝边框AI检测码垛一体机。欧普泰还展示了组件生产工艺全链Ai系统解决方案,包括串EL-Ai+串返修、叠层Ai外观检+汇流条检测、组件EL/外观-Ai检+组件返修、线扫AI、灌胶/边框AI检、二道玻璃Ai检、上下工装机器人和终检外观AI检等。

接线盒激光焊接机,凭借先进的激光技术,可实现接线盒的精准、高效自动焊接,确保焊接质量稳定可靠。其工作节拍仅需13s,有效满足生产线的高效运转需求,大幅提升生产效率。

3D 接线盒虚焊检测(Ai),能精准检测各类接线盒组件的焊接质量。通过模拟挑拨动作,结合 3D 相机对汇流条高度进行精密检测,高效识别虚焊等缺陷,确保检测结果的准确性与可靠性。

铝边框检测码垛一体机,能够高效完成边框缺陷检测与码垛作业。它搭载高清线扫相机,可精准识别边框表面划痕、缺角等二十余种缺陷,配合先进的自动化设计,实现从检测到码垛的全流程自动化操作,有效减少人工干预,提升生产精度与稳定性。

明日精彩继续,就在:

7.1H-B120(光伏电站Ai检测服务展区)

2.1H-B220(组件Ai检测展区)

On June 11th, the 18th (2025) SNEC PV POWER EXPO (Shanghai) was grandly held at the National Convention and Exhibition Center. Optech innovatively adopts two exhibition areas of 7.1H-B120 (PV Power Station Ai Inspection Service Exhibition Area) and 2.1H-B220 (Module Ai Inspection Exhibition Area) to meet the inspection needs of different application scenarios in the PV industry. Through this dual-hall linkage, Optech showcased its comprehensive capabilities as a PV Plant AI Intelligent Inspection Service Provider and an Intelligent Module Factory AI Quality Control Expert, becoming one of the most eye-catching highlights on the opening day.

Two areas linkage, Ai technology covers the whole PV scene

At booth 7.1H-B120, Optech prominently displayed its flagship product, the "Taiyang" system. This system integrates four core functions: unmanned intelligent inspection, visualized operation and maintenance (O M) management, refined fault diagnosis, and digitalized centralized control. Through comprehensive service solutions like OTAuditing?, OTPowerBoost? and asset evaluation, it provides EPCs, plant owners, O M providers, and plant transaction parties with optimization of operational costs, enhancement of power generation revenue, and comprehensive assessment and analysis of asset quality and lifespan.

At the booth, industry experts and professional clients not only interacted with and experienced the TyShine? system''s module quality assessment and defect identification capabilities but also learned about the full service process of OTAuditing? and OTPowerBoost? products through sandbox demonstrations. As the PV industry shifts towards high-quality development, this offers a timely, complete solution for preserving and increasing plant asset value, boosting power generation, and enhancing revenue.

At the invitation of the organizer, Zhao Jun, General Manager of the Sales Management Department of Optech, was interviewed in the Media Center. Mr. Zhao emphasized the highly concealed nature of PV module defects. Electroluminescence(EL) testing is currently the ultimate solution for evaluating module quality, achieving an effect similar to an "X-ray," detecting internal defects including but not limited to micro-cracks, broken fingers, and bright/dark cells – over 200 types of defects. EL testing is currently the only method for internal defect detection and is the definitive means for assessing module health and plant operational status. This detection method is critical across various scenarios: module grid-connection acceptance, module production and O M, plant transaction due diligence, and plant insurance claims settlement.

Mr. Zhao further mentioned that during its full-scope EL inspection service, Optech provides additional value-added services, including but not limited to electric-topology restoration, full-plant 3D digital twin modeling, and module-level O M navigation. These solve the long-standing challenge of pinpointing defects for O M, providing practical tools to improve maintenance efficiency.

2.1 Hall: module AI inspection Technology Leads Quality Revolution

At booth 2.1H-B220, three star products were also unveiled first time, J- box laser welding machine, J-box 3D inspection after welding (Ai),and Aluminum frame inspection and palletizing integrated machine (Ai)applied in the frame production line. Optech also showcased the full chain AI system solution, which are essential part of module manufacturing line, including String EL-Ai+String repair, Appearance/busbar Ai inspection(after stack welding), Module Ai(EL/appearance/frame)+Module Rework, Line-Scan Ai, appearance inspection, Glue filling frame inspection, Upper appearance glass inspection, Automatic installing/unloading robot, Final appearance inspection (Ai).

·Junction Box Laser Welding Machine: Utilizing advanced laser technology, it achieves precise, efficient, and automatic welding of junction boxes, ensuring stable and reliable weld quality. With a cycle time of only 13 seconds, it effectively meets the high-efficiency demands of production lines, significantly boosting productivity.

·3D Junction Box Cold Solder Joint Detection (AI): Precisely detects the welding quality of various junction box assemblies. By simulating a prying action combined with a 3D camera for precise height detection of busbars, it efficiently identifies defects like cold solder joints, ensuring the accuracy and reliability of inspection results.

·Aluminum Frame Inspection Palletizing Machine: Efficiently performs frame defect detection and palletizing tasks. Equipped with high-definition line-scan cameras, it accurately identifies over twenty types of frame surface defects such as scratches and chipped corners. Combined with advanced automation design, it achieves a fully automated process from inspection to palletizing, effectively reducing manual intervention and enhancing production precision and stability.

Tomorrow''s excitement continues, right here:

7.1H-B120 (PV Power Station Ai Inspection Service Exhibition Area)

2.1H-B220 (Module Ai Inspection Exhibition Area)